There are many ways to put information and designs on a package. These methods include in-mold labeling, printing or labeling. In the following, we will talk more about the IML plastic injection machine for in-mold labeling.

What is in-mold label (IML)?

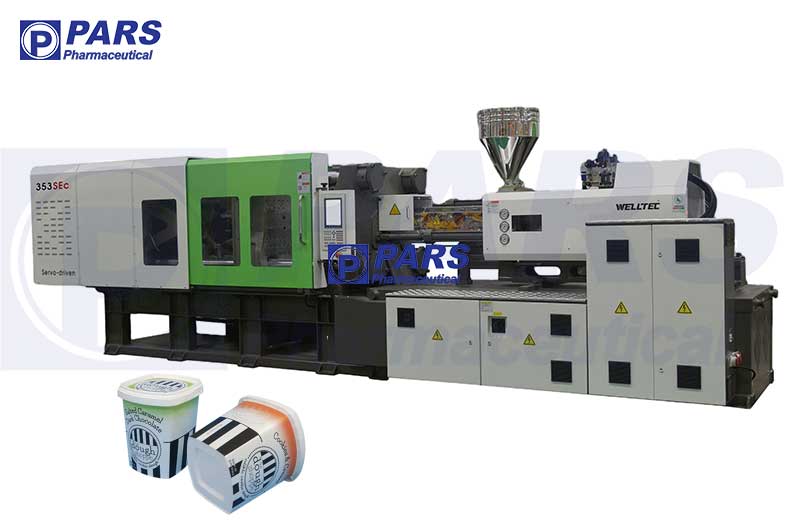

The in-mold labeler injection machine (IML) has the ability to produce a product with a polypropylene layer with your design on it. The polypropylene (pp) label is produced on a flat surface. This allows for an up-to-date and modern design. This label is then integrated during the production of a pp product. The end result is a bucket or lid that forms an attractive and sturdy product.

Production process with IML plastic injection machine

During in-mold labeling, the label is placed in the mold before it forms the product during the manufacturing process. Molten plastic is combined with IML. As the bucket or lid is fused together with the IML, they form an inseparable overall product.

Advantages of IML plastic injection machine

The advantages of in-format labeling are:

A design for the entire package

High resolution design in different colors

Can be used for food (including frozen)

Scratch and tear resistance

Recyclable (both product and IML are made of pp)

With an IML plastic injection molding machine there are no technical limits to the design and a wide range of design solutions can be realized. For example, digital watermarks, RIFD chips, backlight components, etc. can be added in IML.

How to apply IML?

In-Mold Labeling (IML) is very different from other labeling techniques. In-mold labels (IML labels) are placed in molds with IML robot systems before the molds are closed. After the molds are closed, molten polypropylene is injected into the mold. The IML label melts and adheres to the outer wall of the manufactured plastic product. As a result of this process, the final product produced with high print quality is obtained.

What type of label is used in the IML plastic injection machine?

The label used in IML (in-mold labeling) technology is usually made of PP (polypropylene) raw material and dyed by offset printing.

Since polypropylene is a raw material that can withstand high temperatures, it can remain intact in hot injection molding. You can find more detailed information about polypropylene in our article “Types of polypropylene products”.

What are the advantages of using IML plastic injection machine?

The raw materials of in-mold labels (IML Labels) and manufactured plastic products are the same. This makes product recycling easy. This is an environmentally friendly method.

IML labels increase the abrasion and thermal resistance of plastic products.

IML labels improve the waterproof feature of the plastic product in it.

Because IML labeling is a labeling method that is performed simultaneously with plastic injection, it saves time and money.

IML labels produced from polypropylene have a shiny appearance and are eye-catching and have a positive effect on product sales.

IML labeling provides hygiene labels without human touch thanks to IML robot systems.

High Speed IML Method: Direct IML Charging

IML plastic injection machine with the new technology of placing labels in the injection mold called Direct IML Charging. This method has the advantage that there is no high non-isolated voltage inside the mold and we can use a much lower voltage to adhere the label to the mold.

Conclusion

Packaging products produced with IML plastic injection molding machines offer a wide range of product design possibilities. Maximum areas of visual advertising and information are diversified with very different volume options. If you are looking for special IML printing design packaging solutions for your business, you can contact us through WhatsApp or through the email address MS.PARS@YAHOO.COM.

purchase of IML plastic injection machine

If you want to buy an IML plastic injection machine, we have ideal IML plastic injection machines and pneumatic plastic injection machines for you.

The choice of color, label, print or IML depends on various factors. We will be happy to advise you on all types of plastic injection and pneumatic injection machines.

I’ve recommended this website to friends and family who were looking to buy or sell items locally.

The platform’s active user community contributes to a vibrant and dynamic marketplace.